Forklift Work Platform Inspections - Workplace Inspection Checklists

In 2021/22, 29 fatal injuries were due to Falls from a Height

A substantial number of serious accidents occur when people are lifted on the forks or buckets, pallets or stillages placed on the forks of forklift trucks.

Falling from a height accounted for a staggering 24% of all worker deaths over 2021/22 (Source: HSE). Regulation 7(2)(b) of the Work at Height Regulations 20051 places a duty on employers to select the most suitable work equipment for the task to be carried out regardless of the duration of the task. Nevertheless, it is foreseeable (but unacceptable) that people will often use unsafe methods of access to work at height for short duration and occasional tasks. When deciding to use a non-integrated working platform or an integrated working platform, employers must follow all the relevant requirements of PUWER (The Provision and Use of Work Equipment Regulations 1998).

.

Forklift trucks are primarily intended for lifting materials and not people. However, they can be used with working platforms to allow people to work at height in exceptional circumstances only. It is generally accepted that, in conjunction with a forklift truck, an integrated working platform provides a higher level of safety than a non-integrated type. Nevertheless, a non-integrated working platform may be used when it provides a safer means of access than, for example, improvised stairs, platforms or a ladder that would otherwise be used.

To encourage safer working practices, in these exceptional circumstances, occasional use of non-integrated working platforms with forklift trucks is allowed in the UK. The platform must be used and maintained in good working order and repair and in accordance with the instructions provided by the working platform manufacturer.

The Good to Go Safety Forklift Work Platform Checklist is designed for ‘Non-integrated working platforms’ – (you may also refer to them as a forklift truck cage, forklift man cage, a forklift working platform or work access platform) – ie. attachments for use in conjunction with forklift trucks to elevate people so they can work at height, but they have no controls in the platform that allow someone in the platform to control the platform lift height or move the truck; ie all truck and working platform movements are controlled by the truck operator.

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) (regulation 8) requires that lifting operations are properly planned and that work is carried out in a safe manner. For example, there must be a pre-use check of the platform when fitted to the truck and consideration given to factors such as overturning risks. (Regulation 9) requires lifting equipment for lifting people, which includes trucks and working platforms used to lift people, to be thoroughly examined by a competent person at least once every six months or in accordance with an examination scheme.

In addition to PUWER and LOLER, Schedule 2 and 3 of WAHR (Work at Height Regulations ) will apply specifically to non-integrated and integrated working platforms.

The Good to Go Safety system allows you to attach a status tag to the work platform which will permanently display a “Do Not Use” message until such time that a checklist is completed and inserted inside the tag (prior to use). The checklist allows a competent person to complete the relevant pre-use checks of the platform to ensure it is safe to use and to minimise any risk to the user. The completed checklist is placed inside the tag to display the status and date of the inspection, with a duplicate copy retained inside the check book for management records.

Forklift Work Platform Inspection Books - 25 Checklists

Allow workers to carry out pre-use checks and spot potential faults before they develop into a more ..

£6.20

Forklift Work Platform Inspections - Weekly Checklist Kit

Allow workers to carry out pre-use checks and spot potential faults before they develop into a more ..

£37.10

Forklift Work Platform Inspections - Daily Checklist Kit

Allow workers to carry out pre-use checks and spot potential faults before they develop into a more ..

£109.50

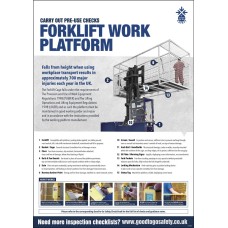

Forklift Work Platform Poster - Visual Inspection Checklist

Our forklift work platform poster has been designed to highlight key components of forklift work pla..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25