Tractor Inspections - Workplace Inspection Checklists

The agriculture industry has the worst rate of worker fatal injury

The annual average rate over the last five years was around 21 times higher as the all-industry rate. More than a third of the workers killed were aged 65 years or older.

A 2018 study “Investigation of UK farmer go / no-go decisions in response to tractor-based risk scenarios” (read the full report). Throws up some key findings relating to attitudes toward maintenance: The majority of farmers would go ahead if a tractor had not had any maintenance done. In many cases the farmer reported they would check the vehicle over before use, though this varied from a quick visual check to a more thorough assessment. Some farmers reported that maintenance is not necessarily required, with tractors rarely subject to maintenance: ‘As long as the machine is operational why would you stop because it hadn't had an oil change for a while?’

The latest HSE report for 2020/21 (available to view in our legislation section here) shows 25 people were killed in agriculture, many of which involved tractors.

The HSE guide to using tractors safely highlights a working handbrake and regular maintenance as two important safety elements. In comparison the majority of the current sample indicated that a faulty handbrake and lack of maintenance were relatively low risk issues. An unidentified fluid leak was viewed with more caution, mainly due to the potential for damage to the tractor. This indicates farmers assess the consequences of risk in broader terms than simply the risk of injury to themselves, they also evaluate the risk in terms of potential costs (e.g. repair bill) and losses (e.g. delay). This consideration of financial costs corresponds with previous research indicating farmers are risk averse in financial situations.

Using the Good to Go Safety tractor checklist to carry out pre-operational checks of the tractor helps farms to meet the HSE guidance and the fact that the systems are relatively low cost means the financial implications will rarely be a negative consideration – especially when you consider the potential consequences of ignoring minor faults – the longer these remain undealt with then the greater the potential damage over time and the greater the potential cost. As with all workplace equipment, regular maintenance can not only improve safety, but it can also extend the lifespan of the machine and help prevent deterioration of parts, which could lead to expensive repair bills and longer downtime.

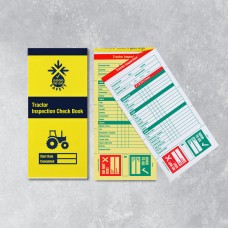

Our tractor inspection book includes guidance notes on what to look for during the tractor pre start checks in addition to the checklist itself. Each book contains 25 individual checklists which, when completed, can be removed and placed inside the status tag (we recommend to attach the tag to the access handhold at the entry point to the cab to maximise visibility and serve as a reminder to complete an inspection). A duplicate copy of each completed checklist is retained inside the check book for audit purposes and can provide evidence that appropriate safety and maintenance regimes are in place in the event of an accident involving the tractor.

Books and tags can be ordered individually or in kit format – the weekly kit provides everything required for a year of weekly checks, while the daily kit includes everything for a year of daily inspections.

Tractor Inspection Books - 25 Checklists

Allow workers to carry out pre-use checks and spot potential faults before they develop into a more ..

£6.20

Tractor Inspections - Weekly Checklist Kit

Allow workers to carry out pre-use checks and spot potential faults before they develop into a more ..

£37.10

Tractor Inspections - Daily Checklist Kit

Allow workers to carry out pre-use checks and spot potential faults before they develop into a more ..

£109.50

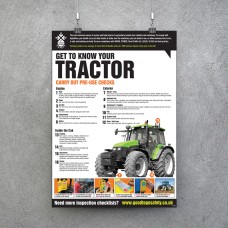

Tractor Poster - Visual Inspection Checklist

Our tractor safety poster has been designed to highlight key components of tractors and reinforce th..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25