A food manufacturing company has been fined following a serious incident at its premises in Wirral.

Sharon Bramhall had been supervising four members of staff as they completed high-level cleaning tasks during a night shift on the 22nd April 2022. She had been acting as a "banksman" as the MEWP turned at a right angle into the warehouse and struck Sharon, crushing her left leg.

The 58-year-old had to have her left leg amputated below the knee following a incident at Baker & Baker Products on Stadium Road, but said that she felt "lucky" and stated "I know i could have died".

An investigation by the Health and Safety Executive (HSE) revealed a series of failings by Baker & Baker Products UK Limited.

The company failed to have in place a suitable and sufficient safe system of work when escorting MEWP’s from a parked position to point of use. They also failed to provide information, instruction and training for the movement of the MEWP and use of banksman and also failed to adhere to their normal practice and company policy to ensure a trained MEWP operator acted as banskman.

Baker & Baker Products UK Limited, of Stadium Road, Bromborough, Wirral, pleaded guilty to breaching section 2(1) and 33(1) of the Health & Safety at Work etc. Act 1974. The company was fined £400,000 and was ordered to pay costs of £7,266 costs.

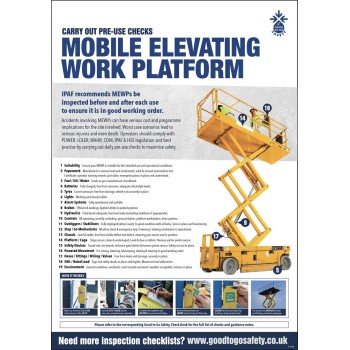

Vehicles continue to be a major cause of fatality and serious injuries in the workplace. All employers should try to keep people and vehicles apart at all times. If segregation isn't possible, a thorough risk assessment should carried out. Most fatal and serious injuries involving MEWPs arise from: Entrapment: operator trapped between part of the basket and a fixed structure, eg when manoeuvring in confined overhead areas of steelwork. Operators may become trapped against the platform controls, and if this happens they may not be able to stop the machine running. Overturning: the machine may overturn throwing the operator from the basket; Falling: an operator may fall from the basket during work activities; and Collision: the vehicle may collide with pedestrians, overhead cables or nearby vehicles. MEWP operators and banksmen should attend a recognised operator training course and received a certificate, card or 'licence', listing the categories of MEWP the bearer is trained to operate. In addition to formal training for the type of MEWP, operators should have familiarisation training on the controls and operation of the specific make and model of MEWP they are using. A programme of daily visual checks, regular inspections and servicing schedules should be established in accordance with the manufacturer's instructions and the risks associated with each MEWP. Operators should be encouraged to report defects or problems. Reported problems should be put right quickly and the MEWP taken out of service if the item is safety critical.

Vehicles continue to be a major cause of fatality and serious injuries in the workplace. All employers should try to keep people and vehicles apart at all times. If segregation isn't possible, a thorough risk assessment should carried out. Most fatal and serious injuries involving MEWPs arise from: Entrapment: operator trapped between part of the basket and a fixed structure, eg when manoeuvring in confined overhead areas of steelwork. Operators may become trapped against the platform controls, and if this happens they may not be able to stop the machine running. Overturning: the machine may overturn throwing the operator from the basket; Falling: an operator may fall from the basket during work activities; and Collision: the vehicle may collide with pedestrians, overhead cables or nearby vehicles. MEWP operators and banksmen should attend a recognised operator training course and received a certificate, card or 'licence', listing the categories of MEWP the bearer is trained to operate. In addition to formal training for the type of MEWP, operators should have familiarisation training on the controls and operation of the specific make and model of MEWP they are using. A programme of daily visual checks, regular inspections and servicing schedules should be established in accordance with the manufacturer's instructions and the risks associated with each MEWP. Operators should be encouraged to report defects or problems. Reported problems should be put right quickly and the MEWP taken out of service if the item is safety critical.