Forklift Truck Inspections - Workplace Inspection Checklists

1 in 5 workplace fatalities are caused by a moving vehicle

Every year there are serious injuries and fatalities, to forklift operators, pedestrians and co-workers, which could have been prevented if properly trained staff had followed safe systems.

Whatever you call them on your site, pre-use, pre-shift or daily checks or inspections, they form an integral part of many companies’ Safe Systems of Work (SSOW). These daily inspections are crucial to ensuring fork lift trucks are in safe working order; providing a regular opportunity to identify any issues before they lead to more serious and costly problems, helping to prevent downtime. They supplement the annual “Thorough Examination” and help identify potential issues, in-between the 12 months period, that could worsen if left unchecked until the next thorough examination.

On average: 1 in 5 workplace fatalities are caused by a moving vehicle, accounting for around 27 deaths per year; in addition 1500 injuries are caused by vehicles every year. (Stats are based over the five years to March 2021. Source: HSE, RIDDOR). ‘Struck by a vehicle’ is the second most common cause of workplace fatality in the UK (25 deaths in the year 2020/21).

In addition to the statutory requirements outlined by PUWER, the HSE’s ACOP (Approved Code of Practice) L117 states: At the beginning of each shift, the operator should check the forklift truck in accordance with the vehicle handbook and document the results. They should report to the supervisor any defects which might affect its safe operation to ensure they are put right.

It’s recommended that pre-use checks should be carried out and documented by an operator when they take control of a forklift truck, in accordance with the vehicle handbook. By encouraging operators to carry out the checks themselves before use, employers will not only allow them to be sure the truck is up to the tasks they expect of it, but it will also encourage them to take responsibility for their own safety and that of those around them.

Good to Go Safety offers an easy solution for forklift management with a flexible safety inspections checklist system that can be used on a pre-use, ad-hoc, daily or weekly basis. Completing pre-use forklift safety inspection as part of your forklift safety maintenance programme ensures both employees and visitors are aware of the forklifts trucks status at all times. Using the forklift inspections ensures your business is compliant with PUWER, LOLER, HSE & FLTA regulations and best practice.

At Good to Go Safety we have often heard stories of checklists being provided to workers but not being completed and often seeing a week’s worth of inspections completed in one go prior to be handed into management at the end of the week – clearly, this is unacceptable and counter productive to safety. By using the Good to Go Safety system and attaching a tag to the truck, anyone walking past that truck can see the current status and date of inspection – removing any doubt of whether the inspection has been completed that day or not.

The forklift safety status tag is highly visible, displaying a “Do Not Use” message until a forklift safety inspection checklist has been inserted - we recommend positioning the status tag at the entry point to the forklift cab to provide an immediate reminder to the forklift driver. Additional reminders such as pre-use safety inspection posters can also help remind drivers to complete a forklift inspection checklist before starting up the vehicle.

Once the pre-use forklift safety inspections has been completed, the forklift checklist is inserted into the tag to display the safety inspection findings and the date of completion. This removes the risk of assumptions. A duplicate copy is retained inside the check book for management records.

Once the pre-use/daily check sheet has been completed, it needs to be securely stored as, in the event of a truck failure or safety audit, they may need to be referenced. Check sheets are to be kept until the next Thorough Examination Report for the fork lift truck has been made.

Forklift Inspection Books - 25 Checklists

Forklift truck inspections help spot potential faults before they develop into a more serious and co..

£6.20

Forklift Inspections - Weekly Checklist Kit

Forklift accidents are a common problem within warehouses, often causing serious injury and in some ..

£37.10

Forklift Inspections - Daily Checklist Kit

Forklift accidents are a common problem within warehouses, often causing serious injury and in some ..

£109.50

Forklift Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

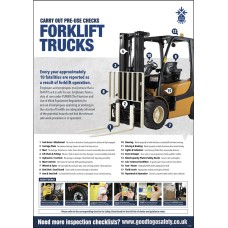

Forklift Poster - Visual Inspection Checklist

Our forklift truck safety poster has been designed to highlight key components of forklift trucks an..

£21.77

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25