News & Events

Pallet Racking Blog

Pallet racking is a warehouse storage system which optimises floor space and loading / unloading times. Pallet racking also known as warehouse racking or storage racking is widely used in warehouses throughout the World due to its versatility and ability to store mass amounts of palletised products, whilst improving the efficiency of warehouse operations.

There are many types of warehouse pallet-racking systems available, each one designed for different applications and facility types. Different pallet-racking systems require different sizes of forklift trucks. The higher the racking systems go, the more sophisticated the forklifts have to be.

As with any work place equipment, pallet racking has risks. Driving forklifts in confined aisles can lead to racking collisions. If a collapse doesn't happen immediately, it will happen eventually. If racking is hit by a forklift, there is a high possibility that the driver will not report it.

Stay up to date with all of the latest industry and legislative news relating to the safety and maintenance of workplace equipment.

We will post blogs relating to HSE prosecutions and HSE accident statistics, safety initiatives and topical events relating

to equipment safety and the consequences of failing to maintain equipment at work across a wide range of industries – from farming

to construction, warehousing to transport and logistics. In addition we will highlight how our Good to Go Safety inspection systems

could help to improve workplace safety and help your company to reduce maintenance costs while complying with key statutory legislations such as PUWER, LOLER and WAHR.

Managing Warehouse Equipment

Thorough inspection checklists of all warehouse equipment are required under Health and Safety law: LOLER 1998 & PUWER 1998

Asking employees to perform pre-use inspections before using forklifts, pallet trucks, racking, ladders, tow tractors, podium steps or any other warehouse equipment is not only a smart and responsible policy to enforce, but is also required by law. Good to Go Safety provides companies easy-to-use inspections which enable competent employees to walk-through a series of ch...

Workplace Equipment Inspections - Construction - Farming - Warehousing

Numerous health and safety accidents or incidents occur every day due to equipment being used in the workplace that is improperly managed, maintained or is not made for the intended purpose. Industries such as farming and agriculture, factories, warehouses and construction are all high risk due to numerous equipment types being used daily.

Employers are required to ensure that all the workplace equipment provided to employees is regularly inspected and maintained in safe working order. Th...

How often should you carry out warehouse racking inspections?

Damaged pallet racking is not only a severe health risk to workers in warehouses, but also a financial nightmare to any business. As an employer, you are legally required to implement and maintain procedures that minimise these risks. Racking inspections are a form of risk assessment. They look for any damage in the racking and can highlight vulnerable areas. The inspection is a crucial opportunity to identify, repair, or replace any areas of damaged racking.

The Health and Safety Executive r...

How to save time and money with effective equipment maintenance

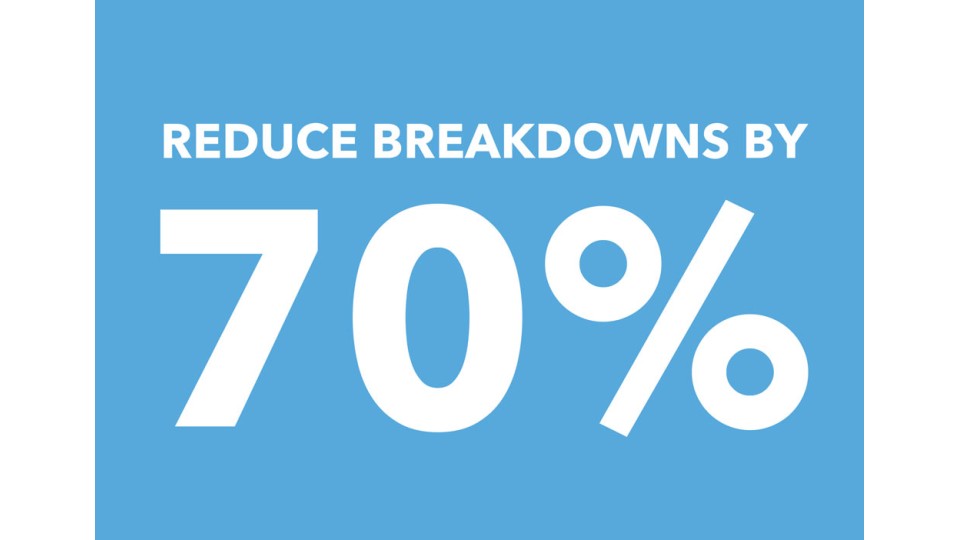

On average, predictive maintenance increases productivity by 25%, reduces breakdowns by 70% and lowers maintenance costs by 25%. Depending on the type of assets, costs and technical sophistication, a broad spectrum of maintenance strategies should be applied. One failing machine may halt the whole production process. Poor maintenance strategies can reduce the overall productive capacity of a plant by 5 to 20 percent.

“Predictive maintenance increases equipment uptime by 10 to 20% while re...

What can you inspect with TakeAIM?

TakeAIM is supplied with a number of pre-installed checklists for the most popular equipment types used for work. If TakeAIMs range of pre-loaded inspections don't have the equipment type you require, you can create your own equipment type on the TakeAIM dashboard. This enables you to create inspections, and ask the detailed question required for even the most unique piece of workplace equipment.

If you'd like to see the equipment types available, plus what is included on each checklist you c...

Even Santa uses TakeAIM

When it comes to checklists, there's no one more proficient than Santa. He has a checklist for good, a checklist for bad and since he found TakeAIM, he's managing them all digitally.

Here's what Santa said about TakeAIM:

As the Holiday season approaches, billions of people World-wide begin counting down the days until they can enjoy family get-togethers, gift giving and / or time off work, ho ho ho. As Christmas approaches some businesses begin to wind down as others see an influx of ...

Factory and Warehousing Safety Tips

Factories and warehouses have numerous health and safety risks. If you fail to manage them, your business may face a number of different issues such as lost working days, injuries and in the worst case scenario, fatalities.

As an employer, you are legally required to implement and maintain procedures that minimise these risks. Safety measures must protect workers from factory and warehousing hazards and enable workers to carry out their jobs safely.

Maintaining good safety will not...

Improve your inspection and maintenance process

Inspections and maintenance of workplace equipment such as forklifts, ladders, pallet trucks, racking etc is a vitally important process to ensure equipment remains in a safe condition. Now we've made keeping track of maintenance and inspection schedules even easier with our range of inspection and maintenance stations. You can ensure your employees have access to their pre-use equipment checklists at all times by providing them with a central location to store their checklists.

When employee...

4 Million Inspection Checklists Sold

To date, Good to Go Safety have supplied over 4 million checklists to companies around the UK.

If you don’t currently know about our multi-award winning inspection systems, you may be wondering why so many people insist on utilising Good to Go Safety rather than simply printing their own checklists in-house? The answers are numerous ….

1. Safety First

From a safety perspective, there is a requirement under PUWER (Provision and Use of Work Equipment Regulations), LOLER (Lifting Operation...

Showing 1 to 9 of 9 (1 Pages)