Pallet Truck Inspections - Workplace Inspection Checklists

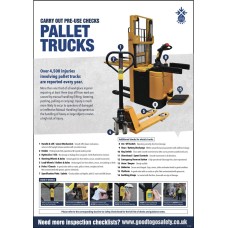

Over 4,500 injuries involving pallet trucks are reported every year

According to the HSE hand trucks, pallet trucks and similar handling aids, such as wheelbarrows and trolleys cause regular injury, yet many managers, supervisors, operators, and pedestrians don’t generally consider the hand pallet truck as a potential hazard.

Businesses shouldn’t treat these pieces of equipment as harmless; although they are much less complex and powerful than other MHE (e.g forklift trucks), accidents are common and operators using them incorrectly often experience bruised and fractured lower limbs and musculoskeletal injuries. Regulation 9 of the Provision and Use of Work Equipment Regulations 1998 (PUWER) requires that those operating any type of work equipment should be trained to use it, to understand the risks involved and to take the necessary precautions. It also specifies that supervisors and managers should receive similar training.

Under PUWER regulations it is the employer’s responsibility to ensure that staff receive suitable and sufficient training. The penalties for failing to train are severe. One supermarket giant was fined £1 million for ‘providing insufficient training’ when an employee lost two toes in an accident involving a powered pallet truck.

The HSE has updated its Approved Code of Practice to clarify that LOLER (Lifting Operations and Lifting Equipment Regulations 1998) applies to high-lift pallet trucks, both manual and powered, that can raise the forks above 300mm. The approved code of practice can be downloaded by clicking here. Most hand pallet trucks will not fall under LOLER but are covered by PUWER and as such must be maintained in a suitable condition and routinely inspected to ensure this remains the case.

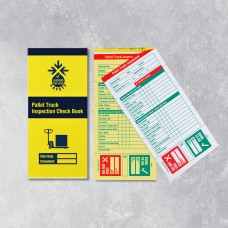

Good to Go Safety provides the ideal solution to pallet truck safety (also referred to as a pallet jack, pallet pump, pump truck or hand truck). Our pallet truck inspection checklist is perfect for both manual and electric powered pallet trucks and is ideal for ensuring pallet trucks are maintained in a good working order.

Simply attach a tag to the pallet truck handle in a position for maximum visibility and then use the pallet truck inspection checklist to complete a pre-use pallet truck inspection. Remove the top copy of the completed checklist and place inside the tag (a duplicate NCR copy is retained in the book for management/maintenance records). The tag will now clearly advise users if a fault has been found and indicate a “Do Not Use” message, or if all checks were satisfactory then users will be advised that the pallet truck is “Good to Go”. The date of inspection is also displayed, making it easy to spot if an inspection has been missed and removing the risk of assuming that someone has completed the checks.

The frequency of pallet truck inspection will be dependent on the findings of a risk assessment with a bare minimum of an annual pallet truck inspection checklist being required. In areas of daily use, in harsh environments or high risk of collisions then the frequency of pallet truck inspections may be increased to weekly or even daily checks. The Good to Go Safety pallet truck inspection checklist is totally flexible to meet your needs.

Pallet Truck Inspection Books - 25 Checklists

Pallet truck inspections help spot potential faults before they develop into a more serious and cost..

£6.20

Pallet Truck Inspections - Weekly Checklist Kit

Pallet truck inspections help spot potential faults before they develop into a more serious and cost..

£37.10

Pallet Truck Inspections - Daily Checklist Kit

Pallet truck inspections help spot potential faults before they develop into a more serious and cost..

£109.50

Pallet Truck Poster - Visual Inspection Checklist

Our pallet truck safety poster has been designed to highlight key components of pallet trucks and re..

£21.77

Pallet Truck Inspection and Maintenance Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25