Scaffold Tower Inspections - Workplace Inspection Checklists

Falls from height remain one of the

most common causes of work-related fatalities

14 people suffered a non-fatal fall from height in the workplace every day in 2019/20, according to the most recent RIDDOR statistics released by HSE.

Although this number is high, the true number is likely to be considerably higher, as employers often don't report when they should. HSE believes that only around half of reportable accidents actually are. The Labour Force Survey also collects data on non-fatal workplace injuries. It uses self-reports from workers, so records a wider range of accidents than RIDDOR. Last year it recorded an est 36,000 falls, which is a horrifying 99 per day.

Many people are injured each year when they fall from towers or when the tower overturns. Towers should be erected by trained and competent people. There are a number of organisations that provide training for the safe erection and use of tower scaffolds and approved “card schemes” can help track and confirm competency.

The incidents that occur with tower accidents are mainly caused by:

Dangerous methods of erection or dismantling – where a safe system is not being followed;

Defects in the erected scaffold – where the tower structure is incorrectly assembled or where a platform guardrail is missing;

Misuse of the scaffold – e.g. where a ladder is used on a tower causing it to overturn or when a person falls while the tower is being moved.

Tower scaffold provision and use must be properly managed and include rigorous scaffold inspection arrangements. They must comply with the standard required for all types of scaffolds, e.g. double guardrails, toe-boards, bracing and access ladder. When the tower is purchased or hired it should arrive with all the necessary components to prevent falls and ensure stability - they rely on all parts being in place to ensure adequate strength, and are more liable to collapse if sections are left out, fitted incorrectly or faulty.

All towers must be inspected following assembly and then at suitable regular intervals by a competent person. In addition, if the tower is used for construction work and a person could fall 2 metres or more from the working platform, then it must be inspected following assembly and then after every 7 days. Stop work if the inspection shows it is not safe to continue, and put right any faults. The result of an inspection must be recorded and kept until the next inspection is recorded. A visible tag system, which supplements inspection records as it is updated following each pre-use inspection, is a way of recording and keeping the results until the next inspection. Additional advice is available from the HSE - click here for more information.

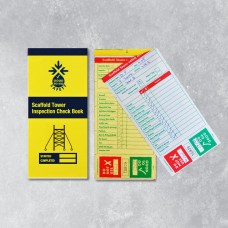

Good to Go Safety offers the perfect solution for Scaffold Tower inspection management. Our Scaffold Tower Checklist helps to improve tower safety, reduce maintenance costs and avoid costly accidents. The checklist system generates carbon copies of each scaffold tower inspection checklist which reduces the chance of an inspection being lost with the duplicate copy being retained within the check book. A copy of the completed checklist can be placed inside a status tag (attached to the tower) to ensure everyone knows the date and status of the latest inspection on site, while the duplicate copy can be retained and stored by management off site for a further three months, in line with best practice guidance.

Using our scaffolding tower inspection checklist ensures you are compliant with WAHR, PASMA & HSE legislation and best practice. The scaffold tower status tag is simply attached to the tube at the scaffold tower's point of entry to ensure maximum visibility. Our universal status tag has been designed to sit flush to a scaffold tower tube using cable ties to reduce the risk of snagging. Scaffold towers should meet the specification of BS EN 1004 and the inspections checks found in the Good to Go Safety inspection checklist check books can help to identify any non-conforming or poorly maintained scaffold tower.

All BS EN 1004 scaffold towers should be supplied with detailed user instructions and critical safety information specifying the use of either the 3T or AGR (Advanced Guard Rail) system of assembly and dismantling. You must follow these instructions and the safety information precisely. Scaffold towers come in many different shapes and sizes, but the Good to Go Safety mobile tower checklist helps identify common pre-use checks to help maximise user safety at all times.

Scaffold Tower Inspection Books - 25 Checklists

One of the main reasons for incidents occurring with Scaffold Towers is due to flaws in its erection..

£6.20

Scaffold Tower Inspections - Weekly Checklist Kit

One of the main reasons for incidents occurring with Scaffold Towers is due to flaws in its erection..

£37.10

Scaffold Tower Inspections - Daily Checklist Kit

One of the main reasons for incidents occurring with Scaffold Towers is due to flaws in its erection..

£109.50

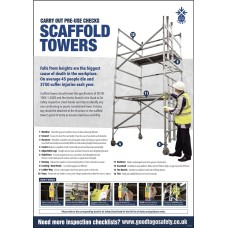

Scaffold Tower Poster - Visual Inspection Checklist

Our scaffold tower safety poster has been designed to highlight key components of scaffold towers an..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25