Straddle Carrier Inspections - Workplace Inspection Checklists

Straddle Carrier accidents are thankfully fairly rare; however, when an accident does occur it often results in fatal injuries

LOLER specifies the need to carry out a thorough examination of Straddle Carriers at least once every year. It is important however not to rely completely on this one inspection. Companies should also complete regular visual inspections throughout the intervening period.

Most often found or used at port terminals. The natural flow of containers through many of today's container terminals sees multiple vehicles and cranes moving within a restricted operational space. While automation and deployment of machine learning technologies can serve to ensure that collisions are minimised, the potential for incidents cannot be underestimated. The interface between personnel and heavy industrial machinery always needs to be carefully considered and managed - safety is the critical priority and everyone operating in these environments need to be protected. Data between 2018-2020 suggest that mobile equipment (trucks, cranes, lift trucks, handling equipment) are involved in incidents accounting for around 75% of the costs of bodily injury claims. Causal analysis of the incidents have identified that most are caused by human error.

A Straddle Carrier otherwise known as a Straddle Truck is a heavy load transportation vehicle. Ensuring that all lifting equipment is fit for purpose is vital to any programme aiming to achieve high standards of health and safety.

Straddle Carriers can be subjected to immense forces. Components such as hoists and cables will see unavoidable wear and tear over time; especially when exposed to adverse weather conditions. Equipment failure can have very serious consequences not just for the load, but also for any plant, building structures or personnel in the surrounding area.

The Straddle Carrier (SC) is a very popular piece of equipment. These carriers can undertake a variety of handling operations such as loading, unloading, stacking and transport of containers between the landside and waterside. Its popularity is due to its space efficiency and flexibility. Traffic incidents are a serious problem at marine terminals, where heavy equipment is used to load and unload ships and move freight from place to place in the terminal. The work is fast-paced, conducted at any time of the day or year, and often performed in inclement weather. Vehicular traffic endangers any worker walking in a marine terminal

In a typical straddle carrier operation, what procedures/methods can be put in place to move towards a zero accident policy? It goes without saying that the operator should be properly trained. But how do you make sure that it is the trained operator that is driving, and what mechanisms can you put in place to monitor and review the safe operation of the equipment? Waiting for the next accident is not an option (Lambert 2009:1 “Improving straddle carrier safety through operational visibility and transparency” Technical Paper)

All container terminal operators recognise the benefits of improving operational welfare for their employees and on-site contractors. Lambert (2009:60) states that it is without doubt that many have also adopted a proactive approach to operational safety, recognising not only the benefits to the welfare of the workers through a safer working environment, but also the additional benefits this will bring to the day to day operation by minimising disruptions and providing a more stable and predictable operating environment. However, how do you achieve the implementation of best practice in a busy container terminal where the operation is spread over a wide area, and just as importantly how do you measure the effectiveness of your efforts? In a typical straddle carrier operation, what procedures/ methods can be put in place to move towards the end goal of a zero accident policy? It goes without saying that the operator of a 60+ tonne machine that is capable of carrying a load of up to 60 tonnes should be properly trained (Lambert 2009:1).

There are many factors that can contribute to traffic incidents in marine terminals. Often, these incidents result from a combination of factors. The following points illustrate some of the most common traffic-safety problems:

1. Unsafe equipment: Broken, improperly maintained, or missing safety equipment, such as lights, seat belts, brakes, and horns, can lead to injuries and fatalities.

2. Inadequate traffic controls Lack of proper signage and lane markings may lead to injuries and fatalities.

3. Condition of terminal driving surfaces

Assuming the risk of deterioration is present with any equipment, the importance of pre-use checks to identify any day-to-day damage, faults or failure cannot be underestimated. The Good to Go Safety Straddle Carrier inspection checklist system is flexible, allowing pre-shift start, daily, weekly, monthly or annual checks to be implemented – every site is likely to have differing requirements and the Good to Go system can be adopted to suit those needs. Written records of completed straddle truck inspections are retained as part of an audit trail, and any equipment that fails an inspection can be withdrawn from service for repair or maintenance with a “Do Not Use” message displayed in the tag for all to see until such time that repairs are completed. Placing the status tag at the entry point to the vehicle helps maximise visibility to all potential users and once the completed checklist is placed inside the tag it will clearly state the status and date of the last inspection, helping remove the risk of assuming that someone has already carried out the checks by clearly displaying if it has been completed.

Straddle Carrier Inspection Books - 25 Checklists

LOLER specifies the need to carry out a thorough examination of Straddle Carriers at least once ever..

£6.20

Straddle Carrier Inspections - Weekly Checklist Kit

LOLER specifies the need to carry out a thorough examination of Straddle Carriers at least once ever..

£37.10

Straddle Carrier Inspections - Daily Checklist Kit

LOLER specifies the need to carry out a thorough examination of Straddle Carriers at least once ever..

£109.50

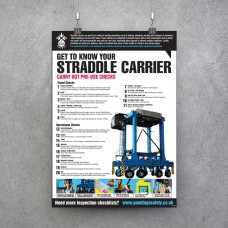

Straddle Carrier Poster - Visual Inspection Checklist

Our straddle carrier safety poster has been designed to highlight key components of a straddle carri..

£21.77

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

Inspection Wallet and Pen

A handy wallet that not only provides additional protection from the elements but also gives inspect..

£6.20

Weather Resistant Inspection Holder

These industrial strength pockets have a press seal fastening to keep important documents clean and ..

£6.31

Inspection Book Dispenser

Allow the storage of checklists in a central location for quick and easy access to important inspect..

£13.25