Equipment Inspections - Daily Checklist Kits

- Product Code: Daily Inspection Checklist

- Contact us for any queries

-

£109.50

- Workplace Inspections for Equipment Inspections - Daily Checklist Kits. Inspections also available for equipment such as Forklifts, Ladders, Scaffolding, Scaffold Towers, Harnesses, MEWPs, Podium Steps, Pallet Trucks, Pallet Racking, Fleet Vehicles - Cars & Vans, Excavators, Trailers, Tractors, Tow Tractors, Loader Cranes, Overhead Cranes, Telehandlers

Our range of Daily Inspection Kits provide you with the perfect solution for workplace equipment that might require a daily safety inspection to be carried out by your maintenance team. The kit contains everything you need for a year's worth of daily inspections for one piece of equipment (based on a 5-day working week) and includes all of the integral components of the Good to Go Safety equipment maintenance systems. The kit includes two status tags to attach to the equipment needing inspected (plus a spare); eleven check books providing a total of 275 individual checklists with content specific to your choice of equipment type; one wallet and pen for storing the current check book; 300 tamper evident seals.

The Good to Go Safety Check Book is an innovative tool for workplace equipment. It allows workers to carry out pre-use checks and spot potential faults before they develop into a more serious and costly defect. These safety checklists are designed to help improve safety, reduce maintenance costs and ensure compliance with legal responsibilities. Each check book contains 25 individual checklists relating to the components and mechanical checks to be completed on the equipment chosen. Duplicate carbon copies of the completed checklists are retained in the book for management records. The book also includes useful guidance notes to remind operatives what to look for during their pre-operation walk around inspection.

The Good to Go Safety Status Tag attaches to all types of workplace equipment - the universal "one size fits all" design eliminates the need for multiple tags, that can cause confusion and clutter. Our status tag has been manufactured from tough, durable polypropylene making it strong whilst flexible enough to withstand the toughest of environments. It has the ability to be riveted, screwed, nailed, cable tied or simply glued to any piece of equipment and the channelled back ensures it will sit flush to poles, handles and tubes. Cable ties are the most common choice for attachment and slide through the recesses at the rear, from the inside of the tag. When secured to a piece of equipment (usually at the point of entry) it displays a "Do Not Use" message until an inspection has been completed and the paper checklist placed inside to display the status and date of inspection. Following an equipment inspection using a Good to Go Safety Check Book, the top copy of the completed checklist is removed, folded and placed inside the tag to display the date and status of the latest inspection. This ensures all employees are aware of the status and removes the risk of assuming an inspection has been completed by somebody. If everything was found to be safe then the tag will show a "Good to Go" message, or if faults were found then a "Do not Use" insert will show in the tag's window - effectively quarantining use of the equipment. Management can clearly see when walking past equipment if an inspection has been missed - allowing them to complete a new inspection, they can also open the tag to see the latest completed checklist - showing when and by who the inspection was completed. This highly visible tag provides clear confirmation to everybody of the latest inspection findings. Our status tag has also been manufactured with the ability to be secured following an inspection with a tamper evident seal which can be inserted at the top of the Status Tag to secure the contents. Once in place the blue tag must be snapped off to enable access to the checklist. The tamper evident seal is an optional extra and sold separately but can be useful for management if they are provided solely to approved "competent" inspectors. Employees will know that if the seal is not in place then the inspection may be invalid. To remove the seal simply pull forward and the "arrowhead" will snap off.

The Provision and Use of Work Equipment Regulations 1998 (PUWER) apply to a multitude of workplace equipment. With such an extensive range of varying types of equipment it is impossible to provide checklists for every eventuality. The fundamentals of PUWER state that equipment is suitable and safe for use; maintained in a safe condition and, in certain circumstances, inspected to ensure this remains the case; used by people who have received adequate information, instruction and training. Ref: HSE GuidanceChoose from an ever growing list of inspection check books and associated kits to make your workplace safer with Good to Go Safety. We provide inspections for Forklifts, Pallet Trucks, Ladders, Racking, Podium Steps, Cars, Vans, Tow Tractors, Trailers, Scaffolding Towers, Fixed Scaffolding, Loader Cranes, Overhead Cranes, Excavators, Forklift Work Platforms, Harnesses, Telehandlers, Mobile Elevating Work Platforms (MEWPs), Scissor Lifts, Boom, Straddle Carriers, Lorry Loaders and more.

The Good to Go Safety Check Book is an innovative tool for workplace equipment. It allows workers to carry out pre-use checks and spot potential faults before they develop into a more serious and costly defect. These safety checklists are designed to help improve safety, reduce maintenance costs and ensure compliance with legal responsibilities. The Provision and Use of Work Equipment Regulations 1998 (PUWER) apply to a multitude of workplace equipment. With such an extensive range of varying types of equipment it is impossible to provide checklists for every eventuality. The fundamentals of PUWER state that equipment is suitable and safe for use; maintained in a safe condition and, in certain circumstances, inspected to ensure this remains the case; used by people who have received adequate information, instruction and training. Ref: HSE Guidance

Choose from an ever growing list of inspection check books and make your workplace safer with Good to Go Safety. We provide inspections for Forklifts, Pallet Trucks, Ladders, Racking, Podium Steps, Cars, Vans, Tow Tractors, Trailers, Scaffolding Towers, Fixed Scaffolding, Loader Cranes, Overhead Cranes, Excavators, Forklift Work Platforms, Harnesses, Telehandlers, Mobile, Elevating Work Platforms, MEWPS, Scissor Lifts, Boom, Straddle Carriers, Lorry Loaders and more.

Each kit contains 275 individual inspection checklists. Duplicate carbon copies of the completed inspection checklist are retained in the book for management records. The book also includes useful guidance notes to remind operatives what to look for during their inspection.

Daily Inspection Kit includes:

• 2 x Status Tags to attach to the equipment and show its status (includes a spare).

• 11 x Safety Check Books provide 275 individual checklists, allowing one to be completed each day of the year (based on a 5-day working week) and the findings displayed inside the status tag. Additional books can be ordered as and when required.

• 1x Check Book Wallet & Pen, to store the current book in use and provide a solid writing surface when completing checklists.

• 300 x Tamper Evident Seals, which can be used to deter and identify unauthorised access to the status tag.

Related Products

Tamper Evident Seals

Tamper Evident Seals are an optional extra which can provide a visual indicator that the checklist i..

£14.06

Universal Status Tag

Designed by experts in the equipment inspection field, The Good to Go Safety Status Tag attaches to ..

£8.40

Inspection Information Station

The information station will provide your workplace with the ideal central location to store inspect..

£233.20

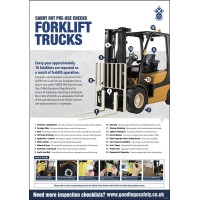

Forklift Poster - Visual Inspection Checklist

Our forklift truck safety poster has been designed to highlight key components of forklift trucks an..

£21.77

Equipment Inspections - 25 Checklists

The Good to Go Safety Check Book is an innovative tool for workplace equipment. It allows workers to..

£6.20

Equipment Inspections - Weekly Checklist Kits

Our range of Weekly Inspection Kits provide you with the perfect solution for workplace equipment th..

£37.10

Tags: Workplace, Equipment, Maintenance, Inspections, Audit, Form, Tagging, PUWER, LOLER, Safety, Record, Check, Books, Construction, Sites, Factories, Factory, Warehouses, Daily, Checklists, Sheet, Log,