Complete in-house checks of workplace equipment. Improve safety, reduce maintenance costs & comply with legislation

Provides visible confirmation of the date and findings of the last inspection

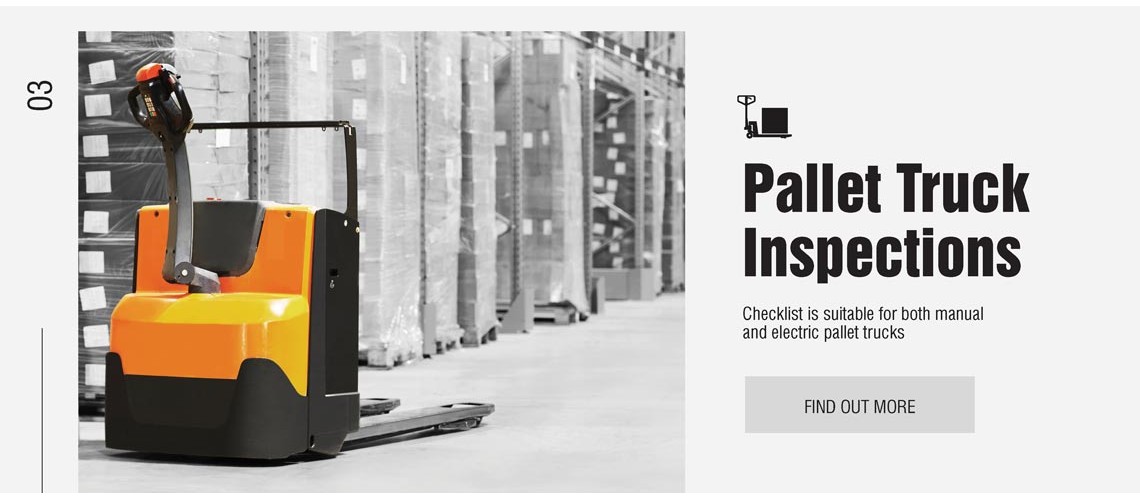

Checklist is suitable for both manual and electric pallet trucks

Ensure essential pre-use ladder checks are completed & reduce the risk of falls from height

Carry out routine visual checks for any damage to help prevent risk of a collapse

Harness checklist covers essential components to help ensure it is safe to use

Record all pre-use inspections by operators

Multi-Award Winning Equipment Inspections & Checklist Tagging System

Good to Go Safety is a multi-award winning system which enables companies to complete safety inspections on workplace equipment. safety inspection checklists enable a competent person to carry out preventative maintenance checks on a wide range of equipment, across many industry sectors. Our safety inspection checklists are just one part of the system; the status tag also ensures visibility of the completed safety inspection checklist (including date and findings) and clearly indicates to employees if/when an safety inspection has been missed or if faults have been found – removing the risk of assumption that it is safe for use.

There are many benefits of using Good to Go Safety as part of a preventative maintenance regime. By implementing regular equipment safety inspections on workplace equipment (such as Forklifts, Ladders, Scaffolding, Scaffold Towers, Harnesses, MEWPs, Podium Steps, Pallet Trucks, Pallet Racking, Fleet Vehicles - Cars & Vans, Excavators, Trailers, Tractors, Tow Tractors, Loader Cranes, Overhead Cranes, Telehandlers) the chance of spotting a equipment fault early are greatly increased ensuring the company can take action before it deteriorates further. Early detection of damaged or faulty equipment can help to prevent accidents and reduce maintenance costs. Good to Go Safety is a simple system that can help improve safety, reduce maintenance costs and ensure you comply with legislation.

The Provision and Use of Work Equipment Regulations (PUWER) 1998 impose specific legal duties on companies to provide, inspect, maintain and operate safe work equipment. With such a wide range of safety inspection systems available, a consistent format and provision of duplicate records of completed checklist ensures company employees and management are meeting their health and safety obligations relating to workplace equipment (under PUWER, LOLER, WAHR and more).

Our equipment maintenance checklist systems are designed for use in virtually all conditions. Suitable for both indoor and outdoor use. The status tag is highly durable and weather resistant and is also universal which means one tag fits all types of equipment - no matter whether you intend to use tags on Scaffolding, Ladders, Forklifts or Pallet Trucks; the tag will sit flush and remain highly visible at all times. We recommend that the tag be fixed at the main access point to ensure maximum opportunity to be seen by potential users.